A few weeks back we began exploring the role of Asset Performance Management (APM) systems and their impact on renewable power generation. To gain further insight into this technology, we turn once again to a recent Avathon analyst interview in which this relationship was investigated in depth.

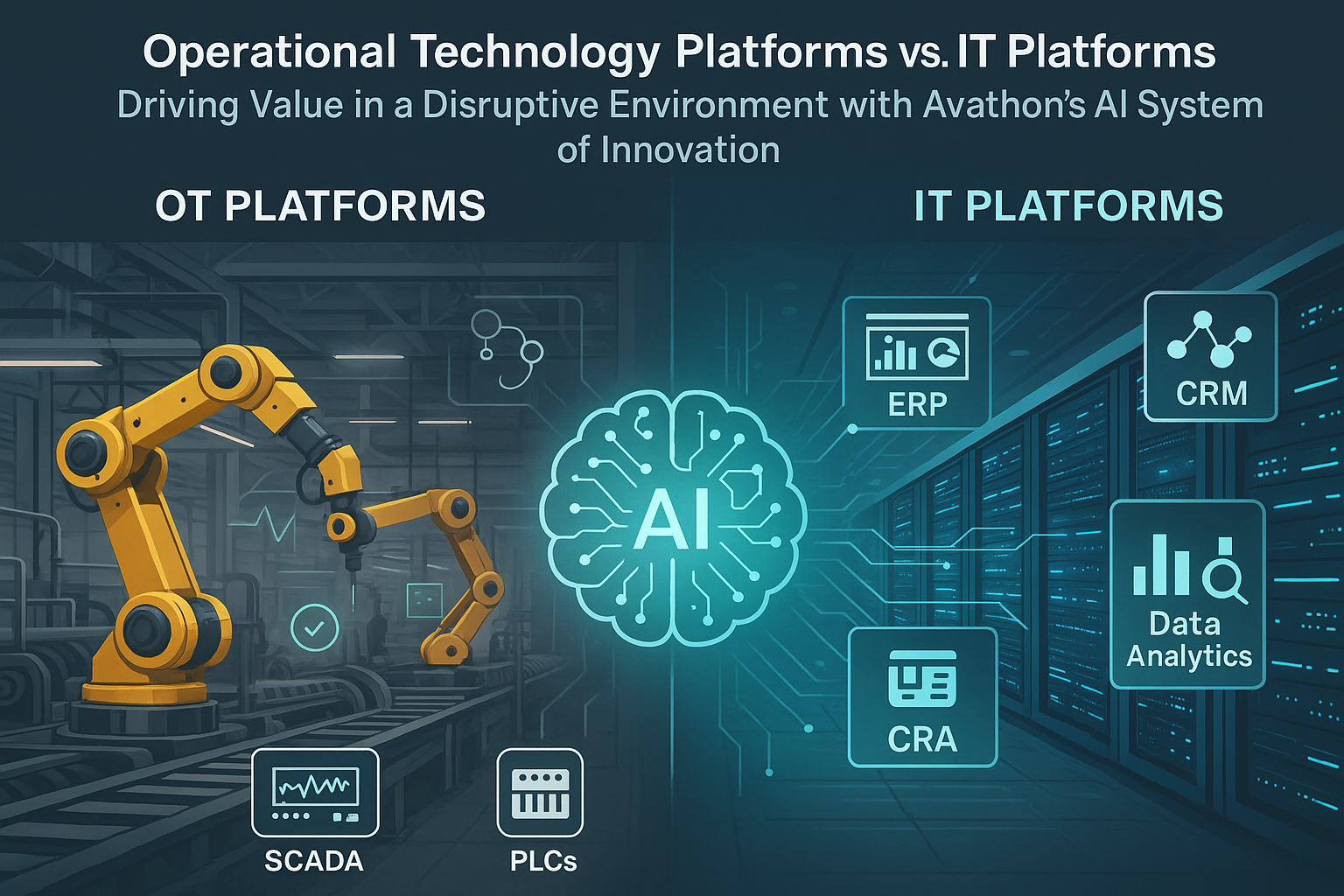

Although the many benefits of artificial intelligence (AI) in the renewable energy space (and indeed throughout the energy industry) are by now well understood (more efficient operations, more accurate forecasting, greater worker safety, to name but a few), the challenges associated with successfully implementing the technology are somewhat less well appreciated, partly because of the newness of the technology and partly because these challenges vary quite a lot from one implementation to the next. Data—its availability, cleanliness, frequency, and timeliness—is a great starting place.

First things first—the data

“If you think about all the different rich data sources available at a typical renewable generation facility,” an Avathon spokesperson says, “the challenge is to integrate all of them and pull them into the core AI models we’re applying. But how do you put a model on top of all those available data sources? It’s about being able to have all those connectors and bring everything into a single place so that you can use all the data in a cohesive manner. AI allows us to connect to more types of data sources, so that, off the bat, we are able to demonstrate faster time to value and increased accuracy.”

Objective assessment of a company’s data availability is typically the first step in answering the million-dollar question ‘Is our company really ready for this sort of solution?’ “Having data accessibility is definitely a big project,” she says. “Ensuring that companies are creating their own central data structure and have the ability to adjust data from all these disparate sources into a single cohesive system is a critical determinant of success. That’s a heavy-lift IT project, and it requires that companies have a strategic thought process about it and think holistically.”

One of the greatest challenges of AI since its inception has been data availability and quality, and the integration of numerous data sources—visual, unstructured text (think hand-written operator notes), streaming performance data (temperatures, pressures, etc.), etc. “A lot of different systems are really good at producing time-series data, but don’t necessarily integrate document data or semi-structured data from work orders or visual data. And that’s one of our differentiators—multiple layers of actionable insight,” the spokesperson says.

“You can have sensor alarms, anomalous time series data, and OEM manuals telling you how things should appear,” she clarifies. “On top of that, you frequently have camera/visual data that’s supplementing all the quantitative info. If you can effectively layer all this information together, you then have a rich collection of resources that can help you figure out the actual issue at hand.”

So, we have the data, but which tools should we use?

Almost as challenging as accessing and effectively using data sources is that of understanding how best to align the various AI-enabled tools with the problem(s) at hand. AI, after all, covers a lot of ground, e.g., normal behavior modeling (NBM), natural language processing (NLP), and visual artificial intelligence (VAI). The list of tools and applications is long and expanding rapidly.

“It’s important to have all these different tools in your toolbox, but also to understand which is best suited for the particular job,” the spokesperson says. “It’s also critical that we’re able to compare with multiple different sets of tools to be alerted to what’s going wrong.”

“The challenge is ultimately one of scalability, whether that’s acres of solar panels, widely-distributed wind turbines, or hundreds of battery storage units. But the way industries have been moving lately is away from pencil and paper to trying to squeeze more hours/minutes out of each day. Employing AI technology and the models we have at Avathon allows customers to do just that.”

“They actually get to clearly understand what they need to do, and implement it faster, with one or two pilot assets. Then, once they’re comfortable that it’s working properly, they’re able to scale it out to the entire fleet automatically, because we have it all on a centralized dashboard where we pull together all the information. We provide that structured workflow and cross functional collaboration for consistent and effective responses so that we’re able to prioritize and act on alerts.”

“You want a system that is malleable to different data sets and applications and groups,” the spokesperson says, “so you have both a system that can handle data cohesively, but you can also compose it in whatever way is appropriate for that customer.”

To learn more about Avathon’s solutions for Renewable Energy, click HERE.