Resources

Find case studies, use cases, white papers, eBooks, and more written by the staff at Avathon.

Avathon Unveils Next-Generation Industrial AI Platform for Aerospace and Defense

Pleasanton-June 25, 2025 – Avathon, the pioneer in industrial AI, has launched the Avathon Industrial AI Platform for Aerospace and Defense. The next frontier in operational intelligence empowers operators to transform the manufacturing and sustainment of new and legacy assets, adaptively and expeditiously manage supply chains and trade compliance, and improve employee safety and productivity […]

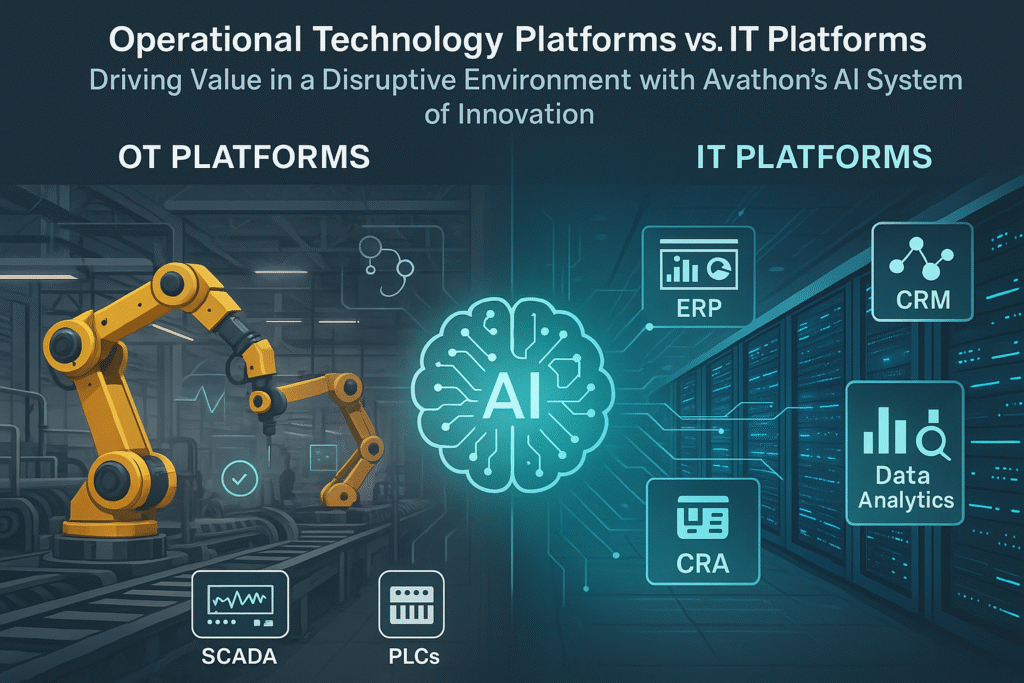

Operational Technology Platforms vs. IT Platforms

Driving Value in a Disruptive Environment with Avathon’s AI System of Innovation By Bart A. De Muynck In today’s rapidly evolving technological landscape, businesses face unprecedented disruptions, from supply chain volatility to regulatory shifts and geopolitical tensions. As of May 2025, companies across industries are grappling with challenges like tariff-driven cost increases, increasing weather events […]

AI: the windstorm for renewable energy

In the race for sustainability, wind turbines have gotten larger every year: taller towers, larger rotors, and higher-rated capacity. This increase in the size of utility-scale wind turbines makes inspections and maintenance interventions at extreme heights, often in strong winds and vibrating structures, inherently dangerous. The industry must undergo a digital transformation toward artificial intelligence to create safer, automated solutions, modeling complex relationships, predicting outcomes, and quickly creating strategic asset optimization strategies.

Can the synthetic workforce help manufacturers navigate a wave of retirements?

America is entering a workforce crisis. Industrial operators are at risk of losing the institutional knowledge of retiring workers. At the same time, they’re struggling with attracting and retaining new generations of digital natives. Approximately 48% of Gen Z employees in manufacturing intend to leave their jobs within the next three to six months. Industrial AI can help with both ends of this generational divide, ingesting decades worth of historical data, trends and learnings while also empowering new workers with the benefits of sophisticated prediction, diagnosis, prescription and automation. This upskilling is critical.

Avoid defense dollar waste with industrial AI supply chain management

Without resilient supply chain management, the military risks wasting the hundreds of billions it spends each year on defense assets. AI-powered supply chain solutions address the challenge of resilience head on, ensuring that our forces maximize their success on the battlefield and taxpayers get the greatest return from their defense investment. “AI-based logistics technology doesn’t just flag supply chain issues—it resolves them,” said Avathon Government President and General Manager Art Sellers. “That gives service branches full visibility and control over their supply networks, resulting in higher operational availability, faster turnaround and a more resilient force.”

Meet the synthetic workforce: Highlights from TiECon 2025

At TiECon Silicon Valley 2025, Microsoft CEO Satya Nadella reminded us that AI is not an isolated breakthrough — it’s the result of decades of innovation across personal computing, the Internet, mobile and cloud. Each wave of progress has compounded, giving rise to the explosive momentum we see in AI today. But perhaps his most lasting point wasn’t technical. “You can’t innovate without empathy,” Satya said during the grand keynote. True innovation means understanding the world through someone else’s eyes — knowing what they need and building accordingly. That message set the tone for my fireside chat later in the day with Claudia Chandra, Chief Product Officer at Honeywell Connected Enterprise.

Avathon Government Digital Maintenance Advisor now available through the Department of Defense CDAO’s Tradewinds Solutions Marketplace

Avathon Government Digital Maintenance Advisor (DMA) solution is available through the Small Business Innovation Research (SBIR) Aisle program from the Chief Digital and Artificial Intelligence Office’s (CDAO) Tradewinds Solutions Marketplace. DMA is currently used by the military to improve maintenance processes for military assets.

Here’s why you’re not getting enough value from your unstructured data

Imagine your technician having a “conversation” with your equipment data to troubleshoot failures and system problems. Or automatically analyzing accident reports and camera footage to make your employees safer. These applications are available today for companies that use AI to interrogate their unstructured data—the event logs, images, customer feedback social media posts and reports that technicians and managers create each day. Without powerful technology, it’s difficult or impossible to analyze at scale, making it effectively invisible to your teams.

Three AI-powered skills you need to tackle the perfect storm of aging workers and assets

Up to $500,000. That’s how much oil and gas operators could lose from just one hour of equipment downtime. These losses can add up quickly too. Based on the most recent downtime figures, industry operators face up to 27 days of downtime per year due to faulty equipment, costing potentially $38 million in lost revenue. If lost money wasn’t problematic enough, a lack of qualified maintenance personnel is exacerbating the issue. Consider this: 50% of energy industry workers are over 45 and expected to retire in the next 5 to 10 years. That’s a lot of subject matter expertise out the door. Meanwhile, equipment continues to age—with four out of ten offshore facilities over 15 years old. It’s a perfect maintenance storm.

Four ways you could be using agentic AI to save lives, using equipment you already have

Did you know that there were 2.6 million workplace injuries in the United States in 2023? While the U.S. Bureau of Labor and Statistics points out that number fell significantly since 2022, any amount of workplace injuries can have an outsized impact on operations. Persistent, overlapping and rapidly changing factors routinely undermine the effectiveness of health and safety programs. With the number of safety hazards as vast as the number of industrial products and processes, how do you get ahead of HSE issues using equipment you already have?

Embrace uncertainty to create supply chain resilience

Is unpredictability—the uncertainty that comes with ever-evolving supply chain disruptions—an unavoidable risk? Can technology help mitigate those issues? Ongoing supply chain disruption, including the ongoing uncertainty of global tariffs, will increase adoption of AI in the supply chain. AI and other transformative technology untangles supply chain knots by modeling uncertainty and managing risk through AI applications rooted in reinforcement and unsupervised learning, stochasticity (randomness) and knowledge graphs.

White paper: How AI is changing the game to drive supply chain visibility, agility and profit

As global logistics and supply chain leaders struggle to adapt to a rapidly changing environment, AI can improve demand forecasting, increase shipping efficiency and ensure delivery reliability.