Workers’ lives and livelihoods depend on observing safety requirements at all times.

Safety awareness and proactiveness are critically important in the oil and gas industry. Preventing vehicle accidents, avoiding slips and falls, and eliminating injuries caused by heavy machinery are all important elements in the safe day-to-day operation of oil rigs, refineries, and other facilities.

The advanced computer vision capabilities of Avathon’s Industrial AI Platform ensures that safety practices are enforced, reducing accident rates and improving oil and gas industry productivity. With Avathon, companies can easily adhere to the life saving rules for safety in the oil and gas industry developed by the International Association of Oil & Gas Producers (IOGP).

Industrial AI mitigates risk in the oil and gas industry

In 2021, there were 95 fatal accidents, a 22% increase from the preceding year. The Society of Petroleum Engineers’ Journal of Petroleum Technology recently published OSHA statistics indicating that in the seven years from 2015 to 2022, there were 2,101 severe injuries among oil and gas extraction workers in the U.S. These incidents include vehicle accidents, falls, explosions/fires, and a wide range of other occurrences.

Of all elements in the oil and gas value chain, offshore exploration and production is the most risky. This is due to the combination of explosive gases, confined spaces, high-pressure environments, and other hazards. In addition to the significant injury and fatality rates for the industry, the amount of potential revenue foregone due to lost work time, while extremely poorly documented, is without question in the millions of dollars annually.

Industry fatality rates have decreased somewhat in recent years, thanks to a combination of new safety initiatives. Widespread implementation of AI solutions and programs like the International Association of Oil & Gas Producers’ Nine-Rules framework have led the way.

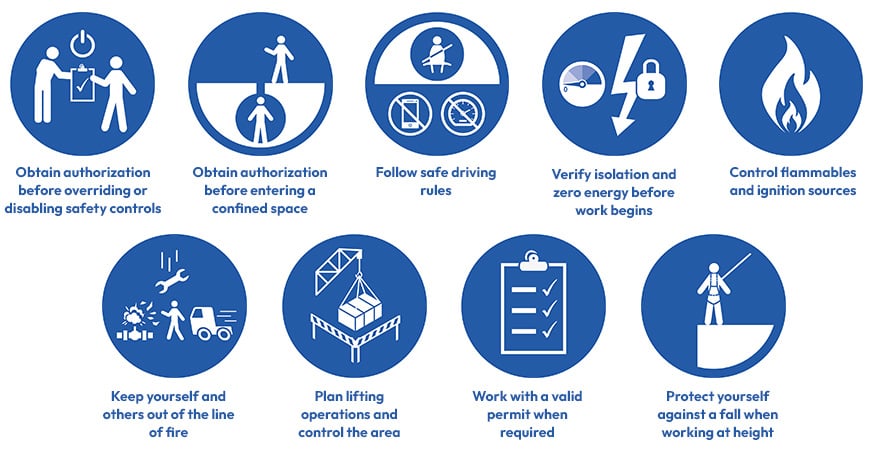

In 2018, the IOGP issued its Report 459, creating a set of nine rules designed to minimize the number of accidents at O&G work sites. The organization found that more than 375 lives would have been saved over the previous decade had these rules been followed.

Industrial AI’s visual capabilities empower proactive safety compliance

Numerous technologies exist that enable O&G companies to implement some or all of the IOGP’s life-saving rules. Among the most powerful of these is computer vision artificial intelligence. Many E&P and refining companies use networks of closed-circuit television cameras to monitor workers’ behaviors and locations, looking for potential hazards or noncompliance violations. But studies have shown that it’s unrealistic for a security officer to see and react appropriately to scenes playing out across dozens or hundreds of camera feeds simultaneously.

Avathon’s Industrial AI platform is a highly scalable enterprise computer vision solution that allows operators to deploy vision-based technology using a low-code/no-code integration framework. It leverages proprietary visual AI capabilities that autonomously understand and react to complex scenes and multi-frame activities— think analyzing live video footage in real time to detect PPE violations.

Visual AI can play an enormous role in keeping O&G operations safe, whether offshore, onshore, or at the refinery. Health, Safety, and Environmental (HSE) management programs that use visual AI solutions are critical to making sure O&G operations adhere closely to the IOGP’s nine rules.

Industrial AI enables companies to prevent accidents by following IOGP’s nine rules

O&G companies use Industrial AI to identify potentially unsafe practices and conditions before they become accidents. Several safety themes that recur throughout the IOGP framework are effectively addressed using visual AI technology. Avathon’s computer vision AI uses an organization’s existing camera infrastructure, whether fixed, drone-mounted, or on mobile phones. The technology is uniquely equipped to tackle the challenge of ensuring safety in the workplace, not only by analyzing specific images but by contextualizing what it sees. The system can alert for everything from missing PPE to an action a worker is taking, particularly if they are not certified for that task.

AI-enabled real-time video analysis is a powerful tool for ensuring HSE performance in the O&G industry, whether off-shore, at refineries, or even at retail locations. Avathon’s Industrial AI computer vision application provides a wide range of capabilities that do not require on-staff data science expertise or resource-intensive manual analysis of video feeds. Users achieve significant safety benefits through simple, intuitively designed interfaces that allow flexible operations while ensuring continuous awareness of safety events or potentially hazardous conditions. The key to ensuring workplace safety is proactive awareness of the conditions that can lead to accidents. By focusing on risks like those highlighted in the IOGP Nine-Rules framework, Industrial AI’s visual technology makes that possible.

Learn more about Avathon’s computer vision AI technology and how it enhances safety in the oil and gas industry.