The oil and gas industry already uses AI to drive process improvement, asset performance management, safety optimization, and regulatory/environmental compliance. But the pace has grown dramatically in recent years with the advent of new technologies like visual and generative AI.

Some of the most important AI-driven improvements have come in the health and safety field. This is true in both refining and across the full spectrum of exploration and production activities, both offshore and onshore. It is incumbent on operators to take every available step to minimize risks to workers.

“Oil, gas and petrochemical refineries are considered some of the most dangerous workplaces in the world and, as such, are subject to stringent regulations and standards of safety imposed by local, state and national regulatory bodies,” writes Avathon’s Jason Chadee in a recent article for Hydrocarbon Engineering magazine. “Ensuring compliance often involves inspections, audits and preventive maintenance activities, which add additional layers of complexity to maintenance operations and demand high levels of attention to detail, data and documentation.”

Safety programs and practices are of utmost importance in refinery environments. Workers’ lives, as well as company operations, depend on observing all safety requirements at all times. One way AI is confronting this challenge is through computer vision applications. This AI tool enables operators to configure and deploy sensor-based applications (sight but also sound and even smell) using a worksite’s existing network of cameras. It leverages proprietary visual AI technology to autonomously understand and react to complex scenes and multi-frame activities. Companies can now use AI to analyze live video footage in real time to detect PPE violations, hazardous area encroachments, etc., and deliver proactive mitigating warnings and alerts.

Industrial AI also fuels efficient and effective oil and gas production

As important as safety is in a refinery environment, it’s also critical that the plant operate efficiently and deliver its portfolio of products in a timely and dependable manner. That’s where prescriptive maintenance enters the picture. This is particularly challenging given the age and complexity of the typical refinery asset base.

“Unplanned downtime is one of the most significant sources of lost revenue and a major driver of extra costs in any manufacturing environment, but even more so in refineries and petrochemical plants. Aging infrastructure poses a significant challenge to refineries,” Chadee writes. “The average age of U.S. refineries is 80 years old, and many are centenarians. Refiners in the US alone are estimated to lose around US$6.6 billion/year due to unplanned downtimes. Maintenance teams are tasked with balancing the need for reliable output with managing the increasing risks associated with aging equipment.”

In an effort to manage downtime and safety issues, refineries have over the years implemented a wide range of technology. Visualizing all the data in one place meant operators could theoretically draw conclusions and take actions to enhance productivity and improve safety standards. The practical outcome was, though, a vast inflow of data that quickly became unmanageable.

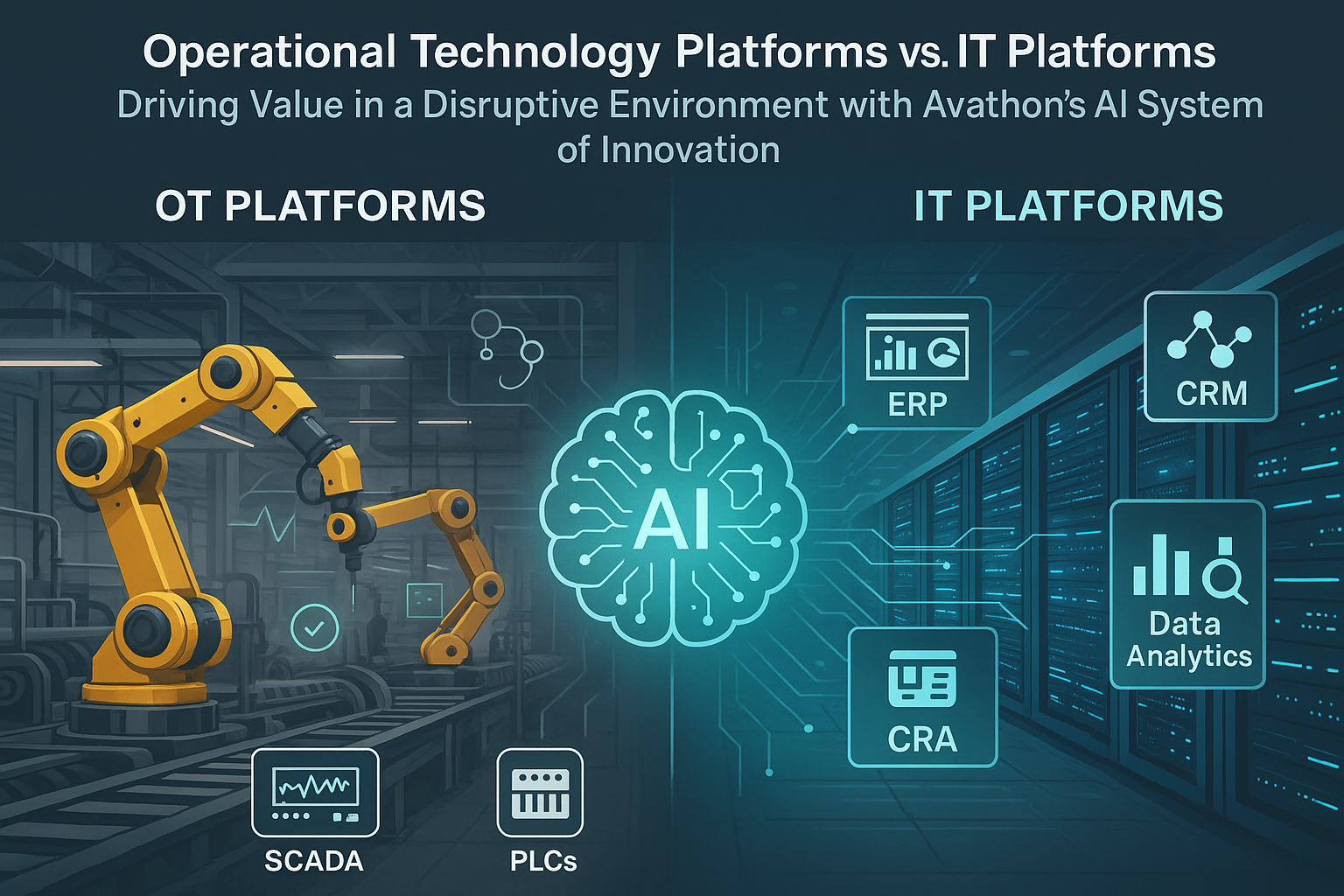

Industrial AI is the core of oil and gas digital transformation

“AI has the unique ability to ingest huge amounts of data from multiple sources, analyze the data sets for key trends and connections, and make appropriate recommendations,” Chadee notes. “AI can also significantly reduce false alarms and alarm volume so that operators can focus on what is truly actionable. This enables predictive to prescriptive workflows, automated data integration, automated model-building, planning and visualization toolkits, generative AI workflow solutions, and more. It ‘learns’ from diverse structured and unstructured data types to unlock actionable insights, reduce costs and optimize processes.”

Refineries have embraced AI to deliver a complex array of products efficiently and cost-effectively. They are doing this while ensuring regulatory compliance, maintaining worker safety and achieving sustainability goals. An integrated approach to operations optimization is required—one that evaluates hundreds or even thousands of data points in real-time from interconnected assets, processes and systems. The oil and gas industry relies heavily on automation technologies to overcome its unique challenges, such as optimizing operations and safety, and ensuring a reliable supply of energy in the face of pressures to operate in safe and environmentally responsible ways.

To learn more about the rapidly growing role of AI across the full oil and gas value chain, visit our website.