Articles

Read articles by the Avathon staff on artificial intelligence and how AI is transforming industry

The Secret of AI Success: the Human-AI Partnership

To achieve successful AI implementations in 2026, organizations must move beyond treating technology as a standalone feature and instead prioritize a deep Human-AI Partnership. While AI agents are capable of automating mundane, high-transaction tasks through “Networked Intelligence,” the ultimate success of these initiatives hinges on the strategic vision and institutional knowledge that only humans provide. The path to a resilient, profitable future is clear: it starts with a relentless, strategic focus on data quality, seamless end-to-end integration, and a commitment to empowering the workforce through the human-AI partnership.

AI and the Industrial Productivity Revolution

Productivity is about accomplishing more using fewer resources, including humans, materials, and energy. AI improves industrial productivity by acting as a force multiplier, shifting manual labor to human oversight. Productivity is enhanced not only by doing things faster, but by enabling systems to be self-healing, predictive, and highly adaptive. AI boosts industrial productivity by automating repetitive tasks, enhancing quality control, and optimizing supply chains, with potential for up to 50% productivity gains in manufacturing. It enables predictive maintenance to reduce downtime, improves data analysis for faster decision-making, and supports sustainability efforts.

Data Centers and AI—Where’s the Power?

The current massive growth phase of construction virtually ensures that local grids will continue to struggle to keep up with data center interconnections—meaning that AI-driven power management is no longer optional; it is a prerequisite for data center operating success. Ultimately, safe and effective power management will be a team effort involving the utility, grid operator, and data center management. The energy management tools enabled by AI tools like Avathon Autonomy for Power & Utilities Operations ensure that the net result will be not only sustainable but will also effectively meet the processing needs of a world of AI users.

Global Trade Management—The Endlessly-Moving Bar

AI has, in recent years, evolved from a “useful tool” to a “digital partner” in Global Trade Management. With the current volatility in U.S. trade policy—specifically the frequent shifts in tariff rates and the emergence of new trade deals like the Taiwan Semiconductor agreement—AI is now the primary capability businesses need to stay compliant and profitable. The global trade landscape is changing dramatically and rapidly, with no end in sight, and with profound consequences for global companies, whether on the importing or exporting side of things. Avathon Autonomy for Global Trade Management delivers the functionality trade professionals need to ensure compliance and minimize operating costs.

Ensuring Defense Asset Readiness with AI

To meet the challenge of delivering high readiness rates, whether it’s for the USAF’s F-16 and C-17 fleets, the Navy’s surface vessels, or the Army and Marine Corp’s ground and air assets, defense maintenance teams require every tool available to keep platforms performing optimally, and artificial intelligence (AI) is at the top of that list of tools. AI’s unique ability to ingest and analyze vast quantities of real-time performance data, evaluate that data for incipient problems, and make targeted maintenance recommendations enables maintainers to have confidence in the readiness of the fleet when they are called upon to deploy to forward locations.

Autonomy and the Case for Industrial Health and Safety

For as long as there has been work to be done, there have been hazards associated with doing it. Whether these hazards take the form of falls, interactions with vehicles and heavy equipment, or exposure to chemicals or other substances, a critical challenge of modern industrial organizations across the globe is ensuring the safety of workers and individuals living near industrial sites and workplaces. With the emergence of artificial intelligence (AI) in recent decades, industry leaders are now employing this technology in a wide range of ways to further minimize health, safety, and environmental (HSE) risks, enhancing worker safety while maximizing productivity.

Why Data Quality is the True Engine of AI Success

In boardrooms across the globe, Artificial Intelligence (AI) is being lauded as the single greatest transformation engine for efficiency, resilience, and competitive advantage in a generation in supply chain. Yet, for every success story, the reality is stark: 95% of enterprise AI projects are a complete failure, representing billions of dollars being “lit on fire” with no measurable return on investment. This profound gap between promise and reality has one single, non-negotiable cause: a broken foundation rooted in low-quality data. To move past this crisis, supply chain leaders must shift their focus from the complex AI algorithms to the simple truth: data is the lifeblood of the modern supply chain.

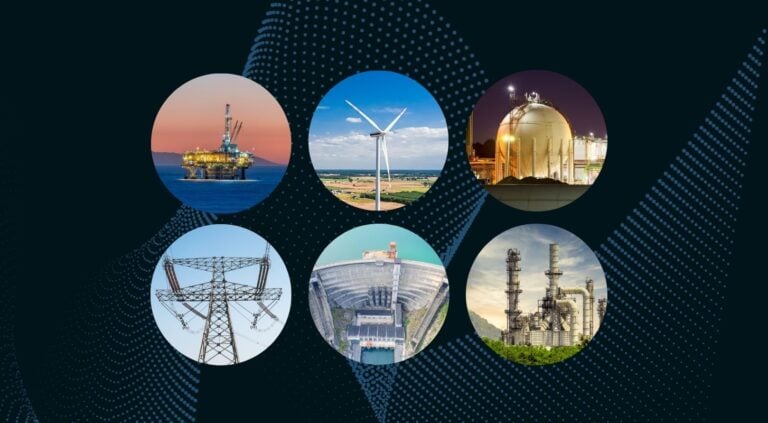

Energy and AI: Powering Up Intelligence

Fresh off Reuters EnergyLIVE 2025 in Houston, we’re still digesting everything we heard and learned about the current state of the energy industry and the issues on the minds of industry leaders. Key challenges and opportunities of course vary depending which industry you happen to work for (oil and gas, electric power, renewables), but there are definitely some consistent themes that emerged from our discussions with line-level managers and executives from these verticals. It will not come as a surprise to hear that top issues center around operating and capital costs, particularly given the parlous state of the economy throughout much of this year and prospects for the coming year.

AI Powers Operating Performance in the Oil and Gas Industry

The oil and gas industry faces profound challenges due not only to the rapid growth in renewable energy and EVs, but also the accelerating pace of technology. AI creates immense value in the operating areas unique to each major energy sector, but there is also significant opportunity for value creation that spans the full oil and gas value chain. Avathon’s Autonomy Platform for Oil and Gas Operations leverages the operating data that upstream, midstream, and downstream operators possess and turns that information into valuable insights that maximize asset performance, production outputs, and worker safety, all using the power of AI.

Artificial Intelligence—A Prescription for Industrial Asset Performance Optimization

Industrial companies spend billions annually purchasing, operating, and maintaining capital-intensive assets. Whether it’s oil platforms, manufacturing plants, power generation equipment, or wind turbines, the challenge is the same: keep your assets producing as economically and for as long as possible while driving maintenance costs down and ensuring product quality remains high. In years past that meant lots of preemptive maintenance to hedge against the possibility of asset failure, maintenance that in many cases was actually unnecessary and incurred undue costs, both in terms of work performed and productivity lost during that work.

AI Drives Opportunity in South Asia

The Asian subcontinent—and India in particular—presents vast and unique opportunities for Artificial Intelligence (AI) due to the area’s scale, diverse population, and strong government focus on digital transformation. Three specific industry verticals—manufacturing, aerospace, and energy—offer especially immense opportunities to leverage AI’s capabilities, supported by government initiatives like the “Make in India” and “Production Linked Incentive” schemes, as well as a strong focus on transitioning to Industry 4.0. AI is critical to these industries for its ability to improve product/service quality, lower operating and capital costs, and increase global competitiveness.

Artificial Intelligence Optimizes MRO Operating Performance

Avathon harnesses the power of AI to turn today’s MRO practices from statically planned and reactive to dynamically planned and proactive. Autonomy for MRO Operations enables users to rapidly detect emerging issues, prescribe the most effective actions, and align the entire maintenance ecosystem in real time. Autonomy for MRO’s wide-ranging feature set equips asset managers—whether aircraft, vehicles, manufacturing equipment, or energy providers—to extract the most value from their asset base while minimizing recurring and capital costs.