Articles

Read articles by the Avathon staff on artificial intelligence and how AI is transforming industry

Keeping Aviation Assets Airborne in Turbulent Times

Avathon’s Autonomy for Aerospace Operations is an integrated artificial intelligence (AI) platform that analyzes supply chain, manufacturing, and maintenance data, delivering actionable recommendations that enable coordinated decision-making across the full range of end-to-end aerospace processes. By leveraging the full power of AI, leaders in the aerospace industry turn complexity into operational advantage—connecting manufacturing, maintenance, and supply chain data to better manage resource constraints, quality challenges, and parts availability for production or in-service fleets.

Forcing the Pivot: What the End of De Minimis Means for Logistics Providers

The suspension of the de minimis exemption (Section 321) is a monumental shift for logistics providers—from giant express carriers like FedEx and UPS to the thousands of global freight forwarders—whose business models were optimized around high-volume, frictionless small parcels. The end of duty-free, minimal-paperwork entry is forcing a profound pivot from a speed-and-volume focus to a compliance-and-data-first approach. With the advances in AI, especially natural language processing and large language models, the industry can effectively deal with these changes.

Agentic AI Amplifies Success in Logistics Planning

Growth in global maritime logistics is forecast to grow at about 2.4% annually through the end of the decade according to the UN Conference on Trade and Development (UNCTAD). And growth across all global logistics is expected to increase at a CAGR of 7.2% from 2025 – 2030, according to a recent report by Grand View Research. But these growth projections have a counterpoint: The sector faces powerful headwinds in the never-before-experienced geopolitical challenges of tariff volatility, embargoes, war, and piracy—resulting in strategic gamesmanship being played out across global supply chains.

Effective Data Management plus Integrated Asset Models Define Performance Success

Reframing the Industrial AI Frontier: Verdantix Green Quadrant 2025 Verdantix has released its latest Green Quadrant: AI Analytics Software 2025, a comprehensive benchmark of how leading industrial AI platforms are redefining performance, reliability, and autonomy across global operations. Among the nineteen vendors evaluated, Avathon was positioned as a Challenger—a designation that reflects both the strength of our platform’s foundation and the pace at which we’re advancing the frontier of applied industrial intelligence.

The Symbiotic Nexus: Decision Intelligence and Decision Execution Platforms in the Modern Supply Chain

Author: Bart A. De Muynck — Advisor, Avathon

The relentless pace of global commerce, amplified by unprecedented disruptions like tariffs, geopolitical shifts, and volatile consumer demands, has solidified supply chain agility as the ultimate competitive differentiator. What began as a simple quest for real-time visibility—a digital dot on a map—has rapidly evolved into a sophisticated pursuit of Decision Intelligence Platforms (DIPs) and, increasingly, their symbiotic partners: Decision Execution Platforms (DEPs). These two technological pillars are fundamentally reshaping how businesses navigate complexity, not just through insights but through automated action, paving the way for truly autonomous supply chains.

Strong Renewable Energy Growth Demands Next-Generation Operational Excellence

Introduction—Renewables are on a strong growth trajectory In March of 2025, fossil fuel electricity generation in the US fell below 50% for the first time, propelled by rapid growth in the renewable sector. Renewable generation is on track to deliver nearly half of global electricity demand by the end of this decade according to the latest report from the International Energy Agency (IEA), this despite the vagaries of politics, subsidies, and manufacturing economics. Despite these potential headwinds, owner/operators need to invest in advanced technology like artificial intelligence (AI) to mitigate these challenges and maximize the utilization of their existing asset bases.

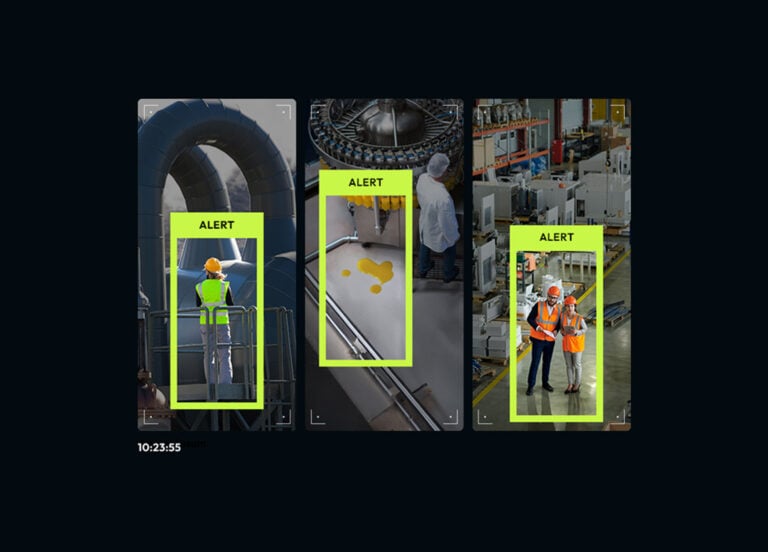

Transforming Industrial Safety and Efficiency: Avathon Integrates NVIDIA Metropolis to Supercharge AI-Powered Video Intelligence

Video data is everywhere—but operational insight is still rare. Industrial sectors generate thousands of hours of surveillance footage daily. From manufacturing plants and oil rigs to logistics yards and aerospace hangars, video is meant to enhance safety and efficiency. Yet, much of it goes unwatched—tucked away in servers until something goes wrong. And by then, it’s often too late. At Avathon, we’re changing that. By integrating the NVIDIA’s Video Search and Summarization (VSS) blueprint—part of the NVIDIA Metropolis platform—into our AI-powered video intelligence solution, we’re making it faster and easier for frontline teams to find what matters most.

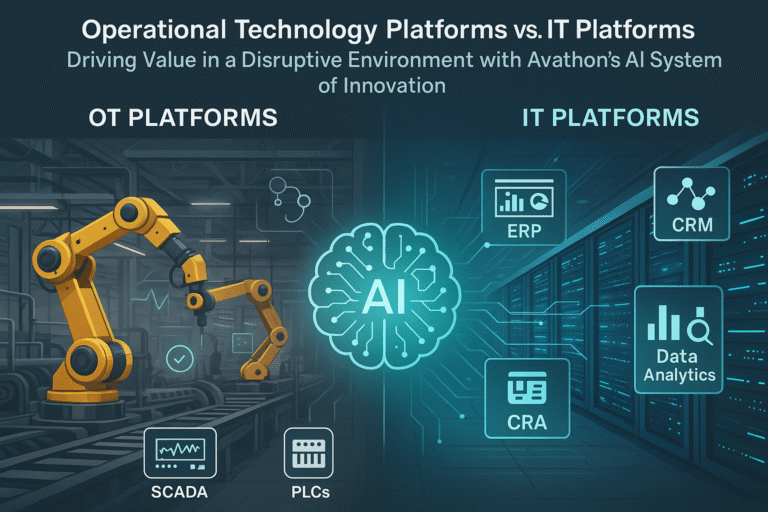

Operational Technology Platforms vs. IT Platforms

Driving Value in a Disruptive Environment with Avathon’s AI System of Innovation By Bart A. De Muynck In today’s rapidly evolving technological landscape, businesses face unprecedented disruptions, from supply chain volatility to regulatory shifts and geopolitical tensions. As of May 2025, companies across industries are grappling with challenges like tariff-driven cost increases, increasing weather events such as drought, fire, and floods, all of which underscore the need for resilient, adaptive systems. Two critical pillars in this environment are Operational Technology (OT) Platforms and Information Technology (IT) Platforms. Understanding their differences, their roles in navigating disruptions, and how a company like Avathon leverages AI to enhance these platforms.

AI: the windstorm for renewable energy

In the race for sustainability, wind turbines have gotten larger every year: taller towers, larger rotors, and higher-rated capacity. This increase in the size of utility-scale wind turbines makes inspections and maintenance interventions at extreme heights, often in strong winds and vibrating structures, inherently dangerous. The industry must undergo a digital transformation toward artificial intelligence to create safer, automated solutions, modeling complex relationships, predicting outcomes, and quickly creating strategic asset optimization strategies.

Can the synthetic workforce help manufacturers navigate a wave of retirements?

America is entering a workforce crisis. Industrial operators are at risk of losing the institutional knowledge of retiring workers. At the same time, they’re struggling with attracting and retaining new generations of digital natives. Approximately 48% of Gen Z employees in manufacturing intend to leave their jobs within the next three to six months. Industrial AI can help with both ends of this generational divide, ingesting decades worth of historical data, trends and learnings while also empowering new workers with the benefits of sophisticated prediction, diagnosis, prescription and automation. This upskilling is critical.

Avoid defense dollar waste with industrial AI supply chain management

Without resilient supply chain management, the military risks wasting the hundreds of billions it spends each year on defense assets. AI-powered supply chain solutions address the challenge of resilience head on, ensuring that our forces maximize their success on the battlefield and taxpayers get the greatest return from their defense investment. “AI-based logistics technology doesn’t just flag supply chain issues—it resolves them,” said Avathon Government President and General Manager Art Sellers. “That gives service branches full visibility and control over their supply networks, resulting in higher operational availability, faster turnaround and a more resilient force.”

Meet the synthetic workforce: Highlights from TiECon 2025

At TiECon Silicon Valley 2025, Microsoft CEO Satya Nadella reminded us that AI is not an isolated breakthrough — it’s the result of decades of innovation across personal computing, the Internet, mobile and cloud. Each wave of progress has compounded, giving rise to the explosive momentum we see in AI today. But perhaps his most lasting point wasn’t technical. “You can’t innovate without empathy,” Satya said during the grand keynote. True innovation means understanding the world through someone else’s eyes — knowing what they need and building accordingly. That message set the tone for my fireside chat later in the day with Claudia Chandra, Chief Product Officer at Honeywell Connected Enterprise.